Labeling machines

ESA series

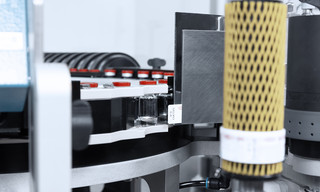

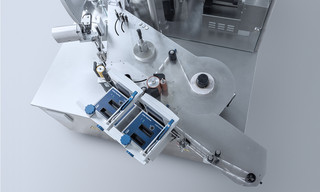

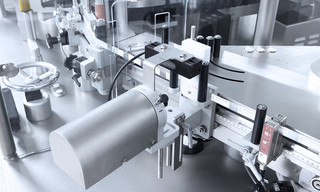

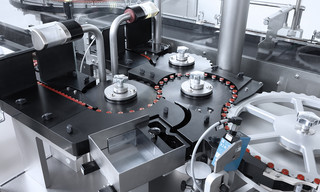

The labeling machines of the ESA series apply self-adhesive labels off the roll to small bottles and vials as well as ampoules, cartridges and other non-stable containers. These continuous-motion labeling machines have a highly compact design. All electrical, electronic and PLC components are integrated in the machines to save space.

New modular label dispenser system

- Precise and gentle container labeling

- Rapid convertibility to various container and label sizes without tools

- Choice of various label printing systems (intermittent/continuous)

- Higher print quality through the use of cutting-edge servo drive technology

- Label printing modules and vision systems combining flexibility, safety and quality

- Labeling process based on the Zero Reject Principle (faulty labels are removed)

New modular label dispenser system

- Precise and gentle container labeling

- Rapid convertibility to various container and label sizes without tools

- Choice of various label printing systems (intermittent/continuous)

- Higher print quality through the use of cutting-edge servo drive technology

- Label printing modules and vision systems combining flexibility, safety and quality

- Labeling process based on the Zero Reject Principle (faulty labels are removed)

HIGHLIGHTS

- Compact design

- Consistent and reliable labeling

- High process reliability

- Modular label dispenser design

| Type of machine | Output | Processing range |

|---|---|---|

| ESA1002 |

|

|

| ESA1025 |

|

|

Wide range of inspection options

Easy and centralized operation

Short set-up time

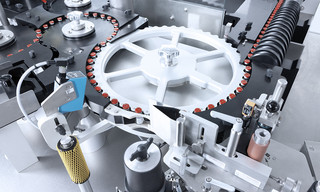

Gentle container transport

- Color ring code scanner

- Label code scanner

- Various printers (e.g. hot foil printers, thermal transfer printers, laser printers, etc.)

- Print check system

- Image processing system for 100 % inspection of printed data such as batch number, date of expiry etc., or of the complete label print.

- Vacuum smoothing roller and label collection roller for faulty labels (ESA 1025 only)

- Label-on-container checks for luminescent or non-luminescent labels

- Label position check (ESA 1025)

- Label splicer system

- Precision tray loading (ESA 1025)

- Double tray loader at discharge (ESA 1002)

- Tray full signal

- Various discharge systems for faulty containers (not available for ESA 1002)

- Options for interlinking with machines upstream or downstream

- Service portal vision system (cleanroom compatible)

- A range of checking and alarm devices and counters

- Software upgrades

- Qualification (IQ/OQ)

Label dispenser

Introducing a new label dispenser featuring a modular design with the following features:- Fast and easy label web loading for quick change-over to various label sizes

- The small number of manual setting values enhances ease of use and avoids potential errors

- The entire dispenser is designed with simplicity in mind, making it easy to clean

- An easily connectable label splicer enables automatic splicing of two label rolls, ensuring continuous production and higher output

- Up to two identical or different coding systems can be seamlessly integrated to enhance performance and boost flexibility

- High flexibility: the modular design enables the easy retrofitting of a second label printer

- Enhanced print quality is achievable in conjunction with high-speed printing when using high-stretch label webs

- The capability to integrate multiple camera systems ensures a high level of process reliability

- The Zero Reject Principle is applied throughout the labeling process

Please note that the advantages listed either do not apply or only partially apply to the following machines: ESA1010, ESA1002