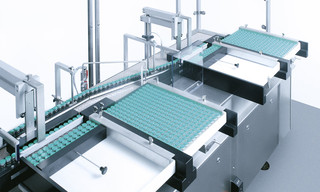

Closing machine

Machine type KS 1025

Fully automatic intermittent-motion machine for closing cylindrical glass, plastic or metal containers, such as bottles and vials with up to two different types of closure. The machine is designed for a wide range of uses in the pharmaceutical, cosmetic and other related industries. It is possible to process all standard types of closure, such as rubber stoppers, droppers, screw caps, pilfer-proof caps and crimp caps, including special closures with pipettes, pump spray assemblies, child-proof closures etc.

HIGHLIGHTS

- Up to two different types of closure

- Compact design

- Size change without tools

- Easy and centralized operation

| Type of machine | Output | Processing range |

|---|---|---|

| KS1025 |

|

|

Pharmaceutical design

- Processing snap-on caps

- Evacuation station

- Application of imprints to containers

- Hot foil printing of plastic containers

- High frequency sealing and ultrasonic sealing

- Labeling station

- Sample discharge

- Service portal vision system (cleanroom compatible)

- A range of checking and alarm devices and counters

- Software upgrades

- Qualification (IQ/OQ)

Barrier systems – RABS

Aseptic ambient conditions free of contamination can be created using RABS (Restricted Access Barrier Systems).

- Passive RABS

- Active RABS

- Closed RABS

- Isolator

Taking the building and room situation into account, these systems provide optimum air flow conditions.