Labeling and assembly machines

SME series

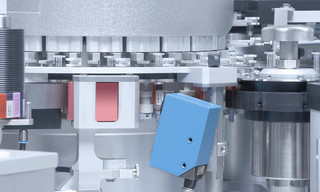

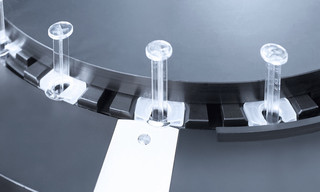

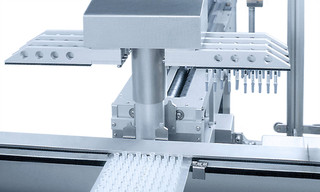

The SME series are compact, continuous-motion machines with a modular design for assembling disposable syringes. The basic module applies self-adhesive labels from a roll to glass or plastic syringes and inserts plunger rods into plunger stoppers without exerting pressure. Two extension modules are also available for expanding production at a later date to include safety-enhanced disposable syringes: a module for the final assembly of syringes with needle guard systems and a further module for assembling backstop components.

HIGHLIGHTS

- Compact design

- Expandable modular design

- Consistent and reliable labeling

- High process reliability

| Type of machine | Output | Processing range |

|---|---|---|

| SME6080 |

|

|

| SME6060 |

|

|

Easy and centralized operation

Short set-up time

Modular label dispenser design

- Various label printers for additional data (e.g. thermal transfer printer, laser printer, hot foil batch printer)

- Vision system for 100 % inspection of additional printed data such as batch number, expiry date, etc.

- Label-on-container check

- Batch-print-on-label check station

- Label code scanner

- Label splicer (ESE 9752)

- Options for interlinking with machines upstream or downstream

- Automatic empty space recognition when labels are missing on the web

- Camera-based inspection system, e.g. to check for correct positioning of the syringe in the safety device

- Discharge of faulty labels

- Backstop application station

- Safety guard application

- Finger flange assembly

- Equipment for processing needle trap labels

- Various reject discharge systems

- Service portal vision system (cleanroom compatible)

- A range of checking and alarm devices and counters

- Software upgrades

- Qualification (IQ/OQ)

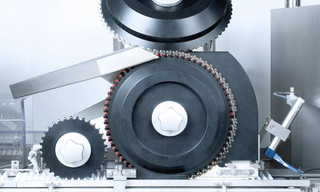

Label dispenser

Introducing a new label dispenser featuring a modular design with the following features:- Fast and easy label web loading for quick change-over to various label sizes

- The small number of manual setting values enhances ease of use and avoids potential errors

- The entire dispenser is designed with simplicity in mind, making it easy to clean

- An easily connectable label splicer enables automatic splicing of two label rolls, ensuring continuous production and higher output

- Up to two identical or different coding systems can be seamlessly integrated to enhance performance and boost flexibility

- High flexibility: the modular design enables the easy retrofitting of a second label printer

- Enhanced print quality is achievable in conjunction with high-speed printing when using high-stretch label webs

- The capability to integrate multiple camera systems ensures a high level of process reliability

- The Zero Reject Principle is applied throughout the labeling process