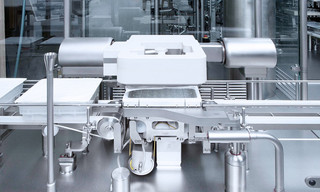

Lid and liner removal

Machine type DVE 9070

These machines remove the lid and liner from tubs automatically. The adhesive around the edge of the tub is heated in order to detach the lid. The lid and liner are jointly removed by means of suction and collected in a bin integrated in the machine base for easy disposal.

HIGHLIGHTS

- Easy and centralized operation

- Compact design

- Pharmaceutical design

- Optimal laminar air flow

| Type of machine | Output | Processing range |

|---|---|---|

| DVE9070 |

|

|

- Free-standing vacuum pump

- Mobile collection bin

- Station for rotating tubs through 90°

- Service portal vision system (cleanroom compatible)

- A range of checking and alarm devices and counters

- Software upgrades

- Qualification (IQ/OQ)

Barrier systems – RABS

Aseptic ambient conditions free of contamination can be created using RABS (Restricted Access Barrier Systems).

- Passive RABS

- Active RABS

- Closed RABS

- Isolator

Taking the building and room situation into account, these systems provide optimum air flow conditions.

Reduced particle process

- Tubs are opened using a patented heating frame.

- The B+S delidding process employs the same method as for closing the tubs.

- In this proven and reliable process, heat is applied to loosen the adhesive bonds.

- This method ensures a reproducible and particle-reduced process with no movement occurring over the open tubs.

- The heating frame design is optimized for laminar flow, ensuring continuous and turbulence-free laminar flow.